FLEX: Data provision at the point of sale with loadbee

The fact that customers abandon a purchase due to a lack of product information cannot be in the interest of the brand manufacturer and the online retailer.

Christian Junker

Managing Director and CEO, Loadbee GmBH

The connection between loadbee and the crossbase PIM system enables companies to provide their product information efficiently and consistently on various online platforms. This provides customers with up-to-date information at every digital touchpoint - a clear advantage that significantly supports the purchasing decision.

Initial situation

Even before the introduction of the crossbase PIM system, FLEX was already transferring data to the cloud-based platform loadbee. However, an automated solution was to be implemented in order to reduce the high cost of manual data transfers and simplify processes.

loadbee GmbH, based in Echterdingen (Stuttgart), offers a cloud-based platform that distributes crucial product information to points of sale and digital devices across all channels. Since its foundation in 2013, loadbee has developed the entire IT solution in Germany and now has over 400 international brand manufacturers among its users.

Procedure

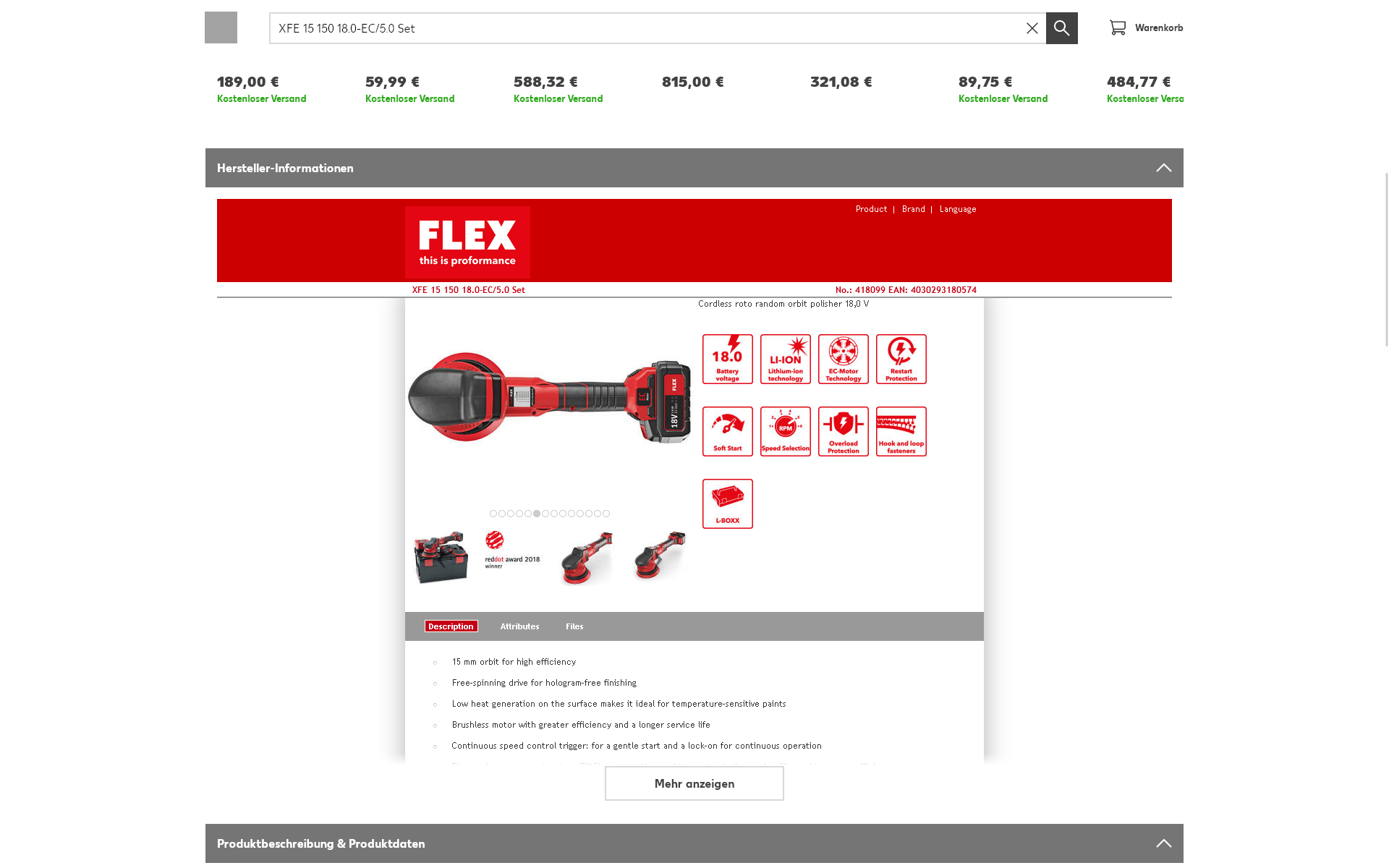

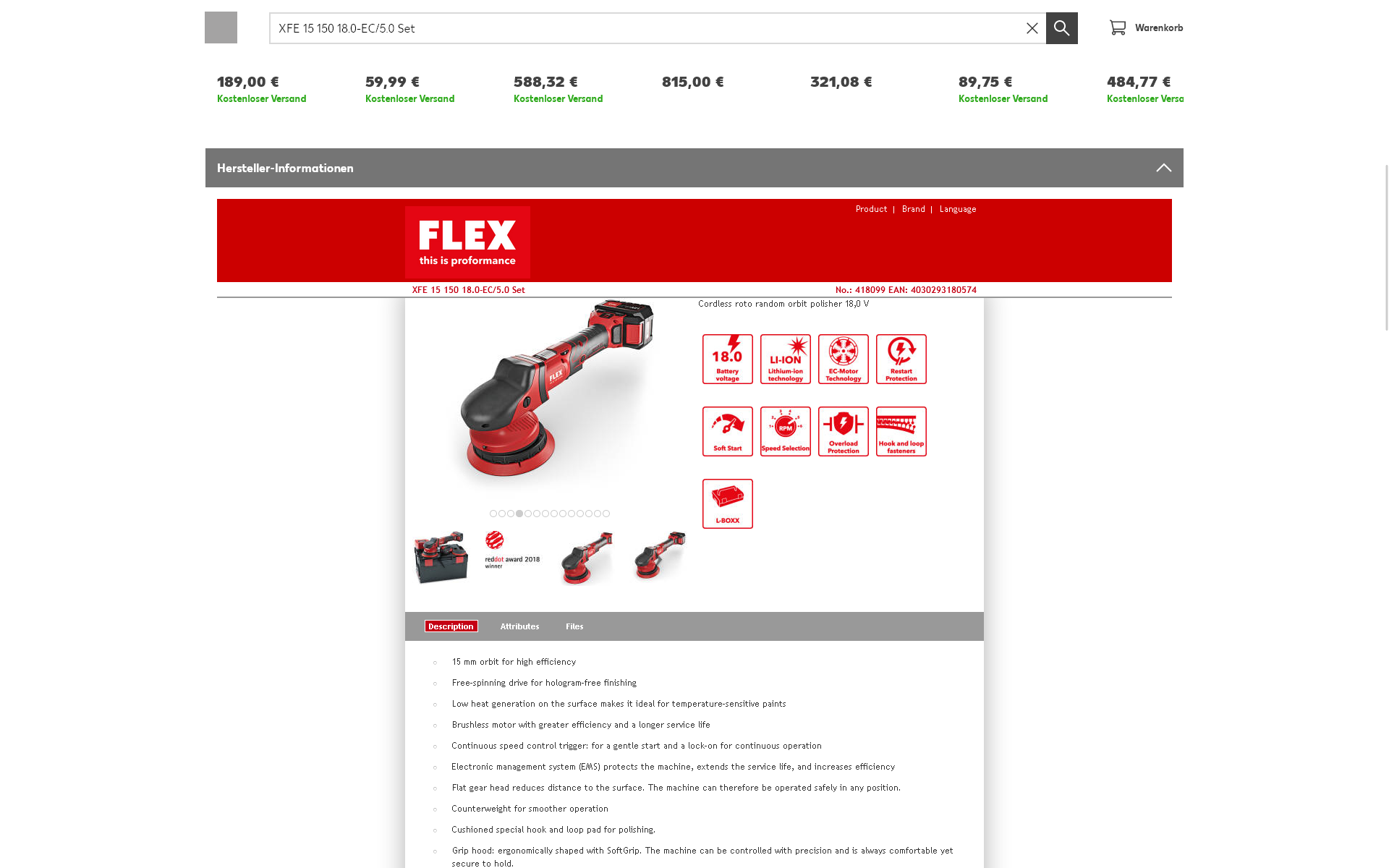

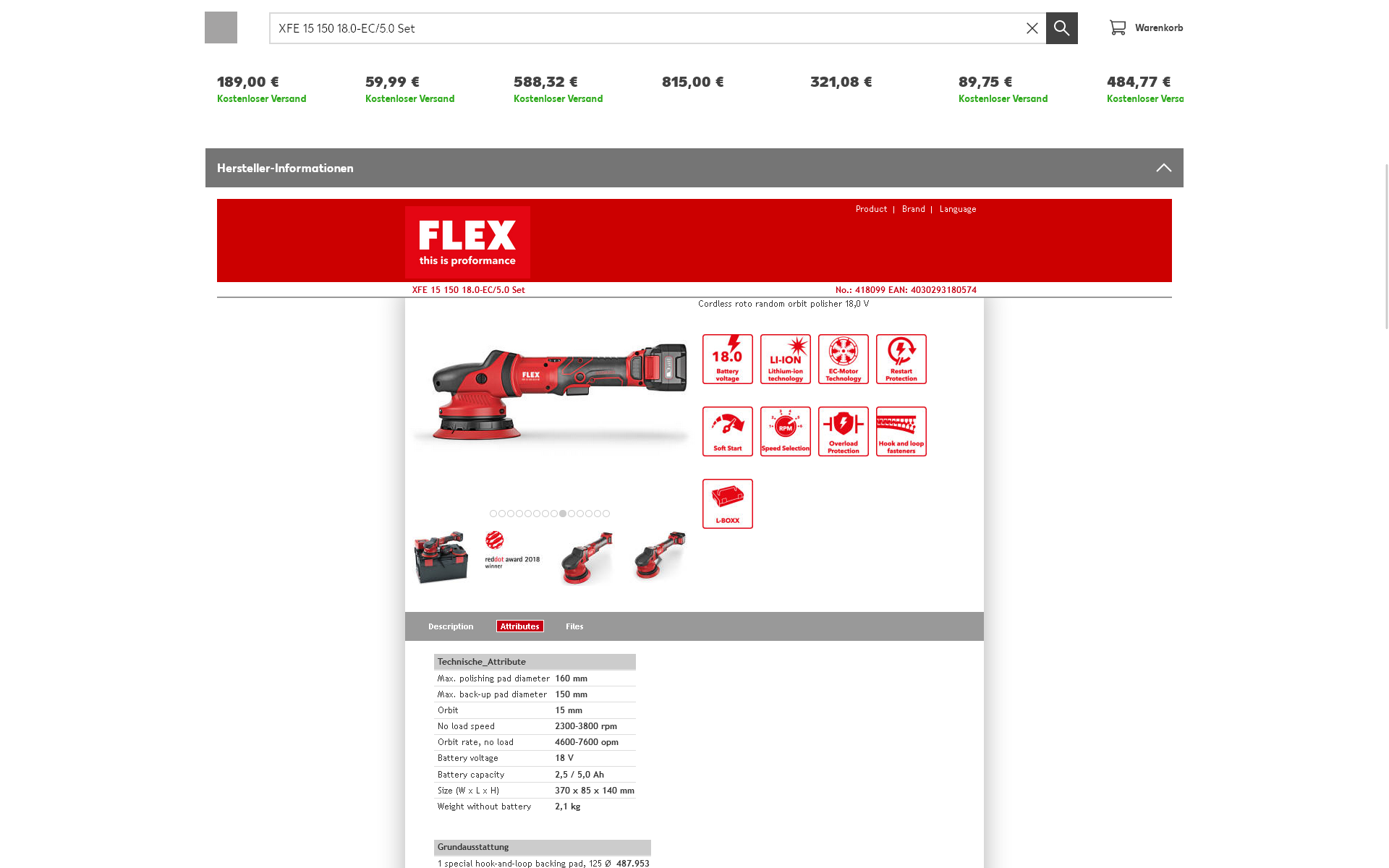

The company uses loadbee to present FLEX products optimally at the digital point of sale (POS). The API interface of crossbase is used to output the data maintained in the crossbase software solution in the desired form. This was programmed in such a way that loadbee is supplied with the required information. The product information always remains up-to-date and consistent thanks to the direct export from the database.

The process can be divided into two API calls:

1. the first leads to the corresponding language-specific output catalog. The language (German, English or French) and the desired product range are selected here. A separate JSON file is then generated that corresponds to the loadbee-specific structure. This enables a direct import.

2. the media files are made available via the second API call. They are combined in a ZIP file and stored in the corresponding target directory.

The characteristics and media files to be output are controlled via so-called output classes, which can be extended by FLEX in the PIM system at any time.

Result

With the integration of loadbee, all relevant product information of FLEX GmbH is quickly and easily displayed on the online platforms used. Around 1,300 articles in three languages are uniformly displayed with technical data, product details and images in various store portals. This partial automation saves a lot of time and increases efficiency - an effort that would be almost impossible to achieve manually. Customers reliably find the information they need to make a purchase decision and enjoy a positive shopping experience.

Advantages

- Data in loadbee-optimized form reduces integration effort

- Automated data transfer via API server

- Improved customer approach through language variants

- Enormous time savings

- Flexibly customizable output of product information in the PIM system

About FLEX

FLEX-Elektrowerkzeuge GmbH, founded in 1922, is a traditional manufacturer of power tools and made industrial history in 1954 with the first high-speed angle grinder, the DL 9. The name "FLEX" has become synonymous with angle grinders, and the term "flexing" is generally used for cut-off grinding. As part of the Chervon Group, the company has an international presence with subsidiaries and sister companies in France, the UK, Belgium, the Netherlands, Italy and the Czech Republic.

Find out more about how FLEX uses the possibilities offered by crossbase: